Custom Copper Tube Bending

Copper is a material that offers excellent thermal and electrical conductivity and tolerates extreme temperatures. These properties, along with its excellent corrosion resistance, makes copper tubing a preferred choice for residential and commercial plumbing applications. Custom copper tubing is also used to manufacture refrigeration and supply lines, and cooling components for lasers and laboratory testing equipment. Finished tubing is joined together using threads, flared ends, compression fittings, and soldering.

Copper Tube Components & Copper Tube Fabrication

The excellent formability of copper makes it easy to bend, though caution must be taken to prevent crushing during the bending process. Copper tube bending is accomplished using different equipment and methods such as rotary draw bending, roll bending, mandrel bending, and ram bending. Each process is unique and provides different benefits, and the company performing the copper tube forming will determine which is best for your specific project.

Contact us to learn more about our customized copper tube forming services.

Custom Copper Tube Bending for All Industries & Applications

With our custom copper tube bending and copper tube fabrication capabilities, we can meet the needs of a wide range of applications and industries that use bent copper tube. We work with OEMs across a broad range of industries and provide specialized secondary operations including welding, flaring, and post-bend threading you can’t find elsewhere.

Plumbing, Heating and Cooling / Copper Tube Bending

Copper’s strength and natural corrosion resistance make it an excellent material for long lasting, low maintenance components. This makes custom copper tubing ideal for plumbing, heating, cooling, and other mechanical systems. We offer copper tube bending in any shape and size you need, whether it’s a straight tube with a single bend for a plumbing line or coiled tubing for a cooling and heating unit.

Custom Copper Tubing for OEM Equipment

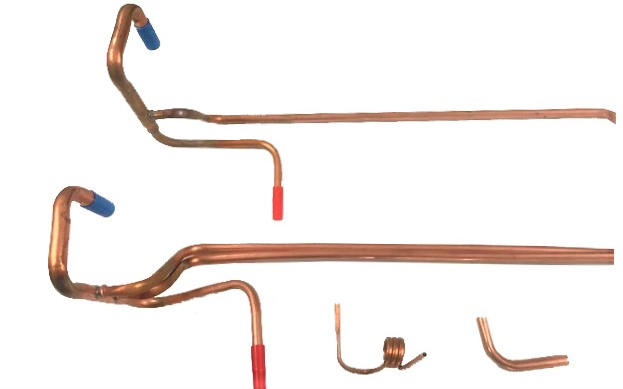

In cooling system applications, water runs through bent copper tubing to reduce and regulate internal temperature. Copper tubing components are used in the cooling systems of many types of equipment and machinery including laboratory equipment, laser systems, and various other applications. This is an example of a 1/8'' linear copper cooling loop, used in the cooling of an instrument. Triad assisted in the OEM design for manufacturability

Custom Copper Tubes for Water Service & Distribution

Copper piping /tubing systems deliver clean, safe water—both hot and cold—for drinking and other potable and non-potable uses. Examples of projects we have completed for this industry include coils for water heating and cooling applications, and custom copper tubes for refrigeration and water supply lines. Examples of 1/4'' & 3/8'' bent copper tube cooling lines used in a laser cooling application.

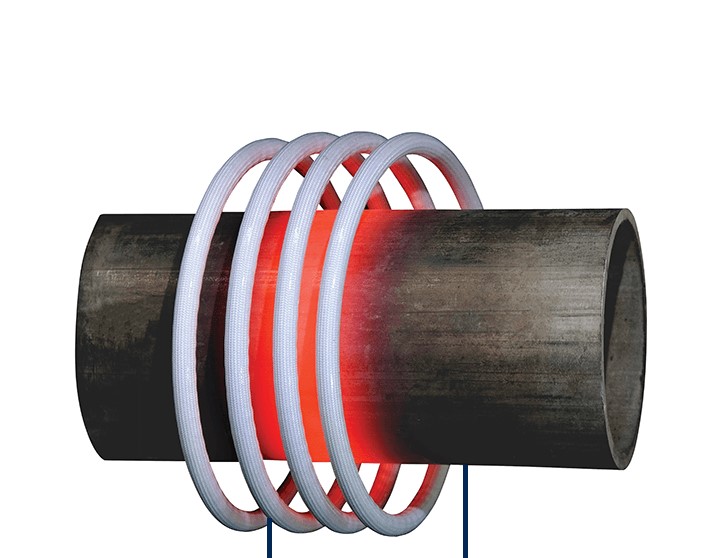

Custom Copper Tube Induction Heating Coils

Induction heating is a fast and efficient method for heating up conductive materials, by supplying an AC current to the coil, thereby generating a fluctuating magnetic field. It is one of the preferred heating technologies for industrial, medical and domestic applications, due to its advantages over traditional heating techniques.

Custom Copper Tube Bending for Heating and Cooling Applications

Triad Products specializes in custom copper tube bending and copper tube fabrication for small to medium production runs ranging from 100 to 1000 pieces. We use specialized equipment and offer custom threading, end configurations, and other services to provide turnkey solutions for your copper tube bending project. Our company is also one of the few vendors that offer post-bend threading and 45-degree flare ends for custom copper tubing.

Because we focus on creating custom copper tube components, our customers know that they’ll receive the highest quality products for their unique applications. And, when you combine our expertise in bending copper tubing with our other manufacturing and assembly services, it’s easy to see why OEMs coast to coast choose us as their single source supplier for custom copper tubing.

Request a quote on the copper tube components you need.

Custom Copper Tubing Sizes

Our custom copper tube bending and fabrication capabilities enable us to provide bent copper tube in a range of sizes to meet your needs. Standard sizes for copper tubing range from 1/8” to 1/2” in diameter. The copper tube sizes we most frequently work with include:

- 1/8”

- 3/16”

- 1/4”

- 5/16”

- 3/8”

- 1/2”

Custom Copper Tubing Grades

Our standard copper tubing is available in many grades including, 122 refrigerator and air conditioning grade tubing, and as specified through customer request. Contact us to discuss your material requirements.

Contact Us for Custom Copper Tube Bending & Fabrication

If you’re looking for high quality, high precision custom copper tube bending, in quantities of 100 to 1000, look no further than Triad. Learn more about what it means to partner with Triad—a trusted OEM manufacturer in tube bending.

Request a quote to learn more about our custom copper tubing and other tube bending and finishing services.