Tube Bending and Forming Services for OEM Applications since 1978

Triad specializes in custom tube bending and forming in medium run quantities of 100 to 1000, with most tooling up to 1” in diameter. Manufactured to your specs, Triad’s customers’ benefit from their turnkey capabilities and secondary operations, to produce both individual components and complex assemblies. Some of the many OEM applications and industries include:

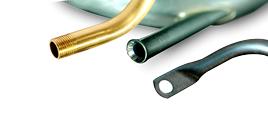

- Brass tubular components that are formed and threaded for the decorative lighting industry

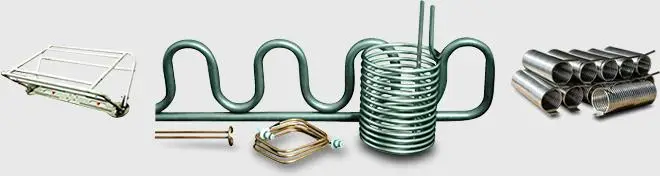

- Tubular supply lines and electrical conduit that are used in the manufacturing of appliances and machines

- Custom cooling coils and lines used to lower temperatures in industrial equipment

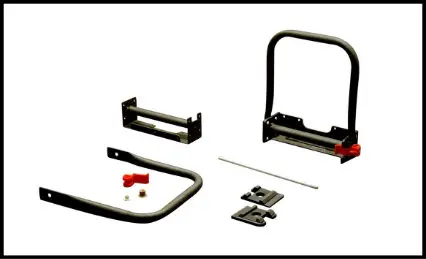

- Bent tubular handles, mounted to the surface of containers or integrated into the OEM’s machine assembly

- Tubular racks and frames, gas and fluid supply lines, and tubular inserts for casting

Triad can thread tubing both pre and post bending, internal or external and to any length

Tubular Steel Handle, that attaches to the equipment and folds 180° for easy storage. Triad redesigned, bent, fabricated and fully assembled the 180° tubular handle, reducing costs by approximately 30%

OEM Tube Bending Services

Providing OEM's nationwide the custom forming and bending of:

- Metal Tubing. Multiple grades of steel, aluminum, stainless steel, copper, and brass tubing to your specs

- Size. Specializing in tube bending 1/8" to 1" in dia.

- Quality Control. In accordance with Mil Spec 45208A

The lighting industry uses cut, bent and threaded brass tubing in the manufacturing of their decorative lighting fixtures

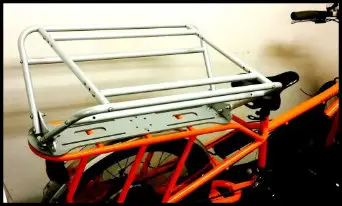

Bent aluminum tubing, threaded, finished and fully assembled with other components, into an adjustable folding bicycles cargo rack

Turnkey Tube Bending Secondary Operations

Triad has the versatility, experience, and secondary operations to both bend and thread simple metal tubing or manufacture complex multi-piece tubular devices. Triad Products is a single-source turnkey supplier for custom bending tubular parts and assemblies for many industries and applications.

- Tube Threading. Pre- and post-bending to any length. Both internal and external threading

- End Configurations. Flattening, drilling, threading, punching, flaring, swaging and assemblies

- Brazing, Silver Soldering and welding. Including MIG, TIG, conventional and resistance welding services, machining conventional and CNC.

- Tubular Assemblies. Bending both metal tubing and manufacturing fully assembled products