Custom Aluminum Tube Bending

Aluminum Tube Bending & Fabrication

Aluminum is a lightweight, flexible, and non-magnetic material used for a wide variety of OEM applications. Its ductility makes it easy to form into bent aluminum tubing of various configurations, ranging from slight bends to tight coils. A natural layer of oxidation protects against rust, corrosion, and some chemicals. Aluminum tubing also has excellent electrical and thermal conductivity and is a better conductor than copper tubing in certain applications.

Custom Aluminum Tube Bending Applications

We specialize in fabricating and bending aluminum tubing for a wide range of industries and OEM applications in quantities from 100 to 1,000 medium run quantities. The examples listed below are just a sampling of our custom aluminum tube bending capabilities. Visit our portfolio of past aluminum bending and fabrication projects.

Aluminum Tubing Grades

We work with materials of various grades for bending aluminum tubing. Options include 6061, 6063, 3003, and others based on customer specifications.

Read our blog article to learn more about the differences between aluminum 6061 and aluminum 6063 and how to choose which is right for your project.

.jpg)

Bending Aluminum Tubing for Propane and Natural Gas Lines

A combination of corrosion resistance and thermal conductivity makes aluminum tube bending a popular choice for propane or natural gas lines in fireplaces, ovens, and other appliances. This type of tubing can take many forms including lines with several angles.

Aluminum Lighting Fixtures

Aluminum is highly reflective and an excellent option for threading electrical wiring in light fittings and fixtures. Since it is also lightweight, the bent aluminum tubing will not add significant weight to your fixtures. Triad also provides custom threading based on your design specs.

Aluminum Equipment Handle

Large Aluminum Cooling Coil

Lightweight Racks, Stands and Carts Made with Bent Aluminum Tubing

Aluminum is a lighter weight than steel, making it a good choice for portable tripods, stands and carts. Other examples of bent aluminum tubing include store fixtures, display racks, architectural trim, framing, painting racks, dip tank racks, and much more.

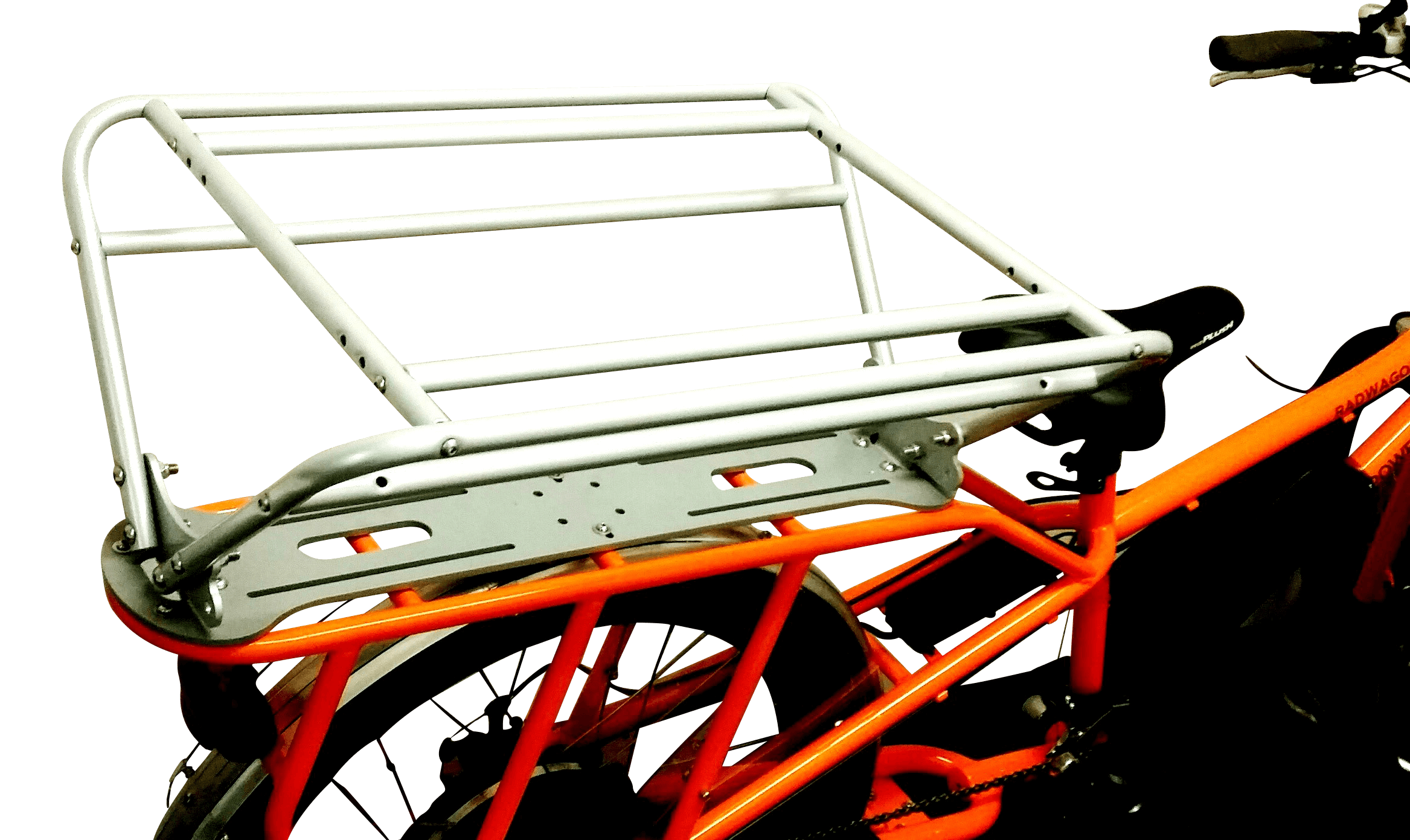

Collapsible Aluminum Bike Rack

3/4'' aluminum tubing, cut and bent. Secondary Operations includes the tube threading, attaching inserts, finishing and final assembly onto a aluminum plate which attaches to the bike. Precision Engineering allows the bike rack to configure from an upright position, to its collapsed position where it lays flat.

Custom Aluminum Tube Bending and Fabrication

Triad Products specializes in fabricating and bending aluminum tubing in quantities from 100 to 1,000. Our focus on medium-sized aluminum tube bending runs allows us to produce the highest quality products available to meet your needs. We also offer fabrication and assembly services including milling, drilling, welding, threading post bending, finishing, and more to provide our customers with aluminum tubing components that match their exact specifications.

Standard Bent Aluminum Tubing Sizes

Triad Products can bend & fabricate aluminum tubing to meet a wide range of sizes. Standard sizes for aluminum tubing range from 1/4” to 1” in diameter.

- 1/4"

- 3/8"

- 1/2"

- 3/4"

- 1" in Diameter

Deciding Between Bent Aluminum Tubing vs. Steel Tubing

The cost of aluminum is typically higher than steel, but some OEMs prefer using bent aluminum tubing because it is approximately one-third the weight of steel tubing. This adds less weight to the final product, which is an important factor for gas lines, frames, racks, and lighting fixtures.

When deciding between bent aluminum tubing and steel tubing, consider the application and operating environment. Aluminum is durable and has a high strength-to-weight ratio, but it is not recommended for high-stress applications and high corrosion environments. For these applications, bent steel tubing is likely the better option. If structural strength isn’t a priority but weight and aesthetics are, aluminum tubing might be the best option.

Our tube bending experts will go over your project and design details to help you decide which material is best for your OEM application.

Contact Us for Aluminum Tube Bending Services

Triad Products specializes in medium runs of 100 to 1,000 in aluminum tube bending fabrication. When you combine our manufacturing and assembly capabilities, you can see why OEM's choose Triad Products as their single source supplier for custom aluminum tube bending. Request a quote to discuss your project and learn more about our custom aluminum tube bending capabilities.